The Sliding Shoe Pump – Built to Last – not to Replace

> Single Cover Access

> Self-Priming

> Dry Running

> Self-Compensating for Wear

> High Suction Lift

The Sliding Shoe Pump – Built to Last – not to Replace

> Single Cover Access

> Self-Priming

> Dry Running

> Self-Compensating for Wear

> High Suction Lift

Sliding Shoe Pumps

Positive Displacement Pumps

The Sliding Shoe pump is unique to all other pumps in the world and offers the advantages of many different pump types in one pump. No other pump has as many unique design features and benefits.

The Megator self priming positive displacement sliding-shoe pump provides exceptional suction performance, versatility, and the ability to pump at constant capacity against heads to 250′ (76m). It can run without harm during dry suction, is self compensating for wear, has a simple design with few working parts and single cover access to its wear parts. It might be said to resemble a reciprocating piston pump, and it has indeed all the well known merits of that type – powerful suction and self priming, constant capacity at varying heads, the ability to cope with rough conditions and to handle a great variety of liquids, viscous or free flowing, clean or dirty. Yet in its simplicity, compactness and smooth flow it more closely resembles the centrifugal pump. It therefore combines the advantageous features of both these two main pump types without their respective limitations.

Benefits

- Self priming

- Operates with dry suction

- Simple to install

- High suction lift

- Constant capacity at varying heads

- Single cover access

- Simple to operate

- Self compensating for wear

- The same pump for water and oils

- Remove the last drop from containers

- Minimal shear/emulsification

Features

- Capacities up to 264 US gpm (60 m3/hr)

- Suction lifts up to 27 ft (8.2 m)

- Viscosities up to 5000 cSt

- Heads up to 250′ (76 m)

- Available in bronze, cast iron & aluminum casings

- Air, diesel, electric, hydraulic or gasoline driven

- Variable speed inverter control

- Direct coupled or belt drive options

- Available assemblies include stationary, skid-mounted & mobile options

Positive Displacement Pumps Resources

Sliding Shoe Pump Assembly

How the Sliding Shoe Pump Works

Self Priming Marine Pumps

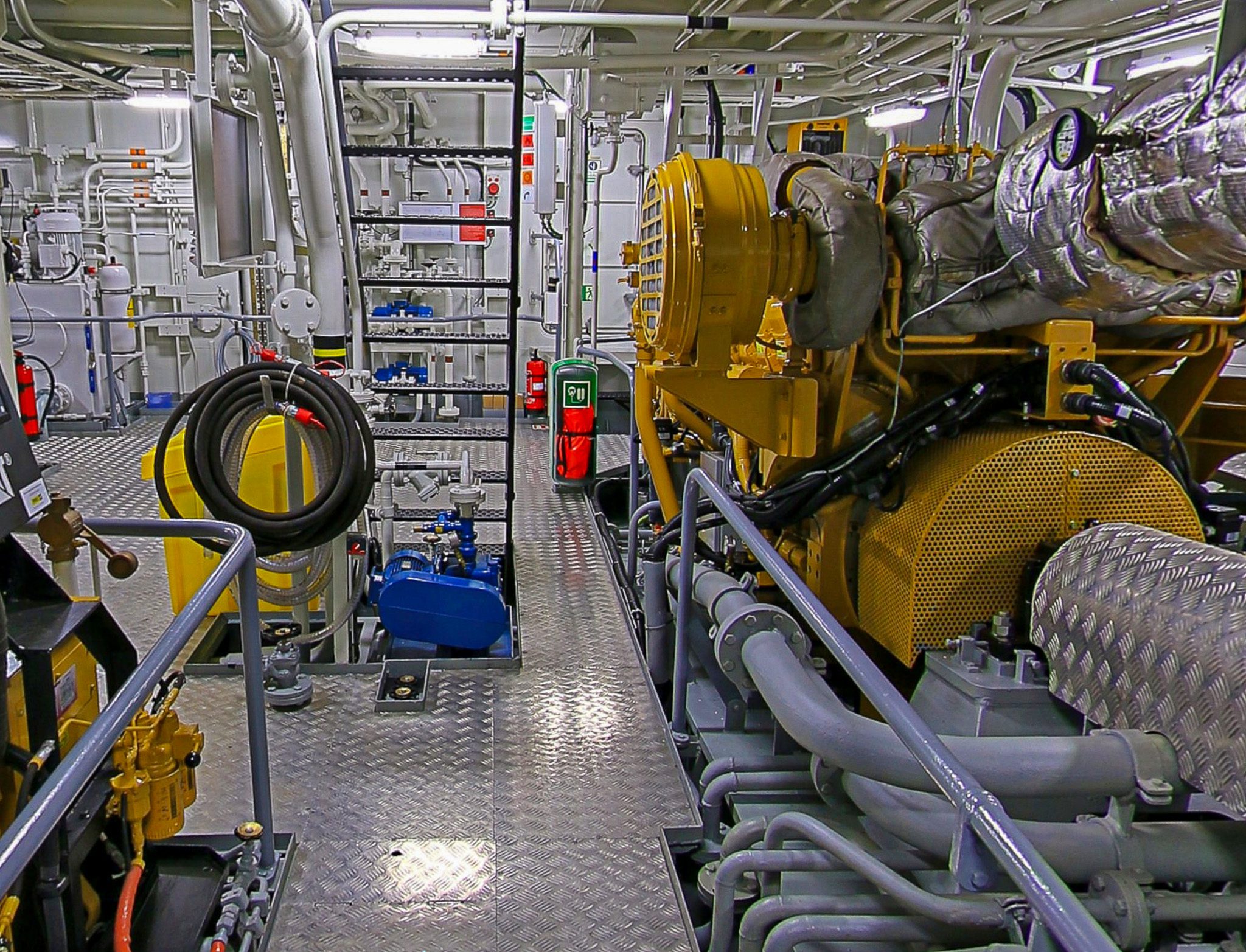

Megator sliding shoe pumps have for many years been selected and installed in the merchant fleets and navies of many countries, including the Royal Navy and United States Navy. The pumps have an unrivalled combination of advantages for marine service within their capacity range, performing with equal efficiency on many of the pumping duties required on-board ship.

Self Priming Bilge Pumps

Self priming combined with high suction lifts and the ability to handle dirty liquids make the Megator positive displacement pump the ideal bilge pump.

Self Priming Sludge Pumps

Self priming positive displacement sludge pumps can handle sludge of low or high viscosity.

Self Priming Grey Water Pumps

Self priming positive displacement grey water pumps will not be harmed if left dry running on an empty grey water tank.

Self Priming Fuel Oil Pumps

Self priming fuel oil pumps will efficiently handle thin liquids that have no lubricating properties.

Self Priming Oil Pumps

The low shear effect of the self priming positive displacement oil pumps prevent oils from emulsifying.

Self Priming Ballast Pumps

The self priming positive displacement ballast pumps will pump at constant capacity to any head within the pumps range.

Self Priming Pressure Systems

Self priming positive displacement pressure systems can be supplied as single, double or triple pump sets and are fully automatic in operation.

Self Priming Purification Pumps

Self priming positive displacement pumps fitted with an ultra violet purification system ensure water supplied on board ships meet the latest hygiene requirements.

Self Priming Low Magnetic Pumps

Self priming positive displacement low-magnetic pumps, are used on a wide variety of applications onboard minesweepers and other Navy vessels requiring low magnetic signature.

Self Priming Black Water Pumps

The ability to remove the last drop from containers make the positive displacement pump ideal for pumping treated black water.

Self Priming Fuel Stripping Pumps

Self priming positive displacement fuel stripping pumps can pump oils and water with high or low viscosities.

Marine Pumps Resources

Sliding Shoe Pump Marine Presentation

Self Priming Industrial Pumps

Modern industrial pumping means much more than transferring a liquid from A to B. Pumps have become the prime movers in innumerable industrial processes and encounter endless combinations of pressure, density, viscosity, temperature, volatility, corrosiveness and solvent action, of solids in suspension and gases in solution. There is no simple and universal answer to these problems, and no one type of pump will cope efficiently with all conditions, but Megator pumps come nearer to doing so than any other single type.

Megator pumps are widely used in a variety of industrial applications which include:

- Mine face drainage pumps

- Aviation deicer pumps

- Engine coolant pumps

- Laundry waste pumps

- Food waste slurries pumps

- Diesel fuel pumps

- Sewage scum pumps

- Caustic liquor pumps

- Syrup transfer pumps

- Chemical sludge pumps

- Lime slurry pumps

- Waste oil pumps

- Paint transfer pumps

- Oil transfer pumps

- Sump drainage pumps

- Leachate pumps

Industrial Pumps Resources

Oil & Pollution Recovery

Ideally suited for pollution recovery duties, Megator pumps are normally supplied as portable sets mounted in a lightweight tubular frame with wheels, but are readily available for static installations. The prime mover may be a gasoline or diesel engine or TEFC electric motor.

The low shear effect of the sliding shoe pump prevents oil from emulsifying. Combined with self-priming, super-suction, dry running capabilities and the ability to pump air and water with a smooth continuous non pulsating flow make it ideal for offloading skimmers.

They will handle clean or dirty oils of low or high viscosity, any mixture of oil and water, any amount of air without loss of prime and are ideal for use with the Megator range of oil recovery skimmers. Providing an efficient method for removing oil, effluent, sewage scum and various other nuisance liquids from the surface of water.

Pollution Pumps Resources

Mining Sliding Shoe Pumps

- Single cover access/Easy to Service

- Self Priming

- Dry Running

- High suction lift

- Constant capacity at varying heads

- Low Shear (to prevent emulsification)

Proven Mine Dewatering Technology

- Runs for long periods with a completely dry suction line, without loss of prime or damage to the working parts.

- Super suction handles high lifts and long suction lines, so pumps can be installed in convenient locations.

- Attaching a number of isolated suction lines reduces the need for multiple pumps.

- Maintenance is quick, simple and can be performed underground without disconnecting pipe work.

- Rapid self priming without the need for troublesome footvalves.

- Self compensating for wear prevents frequent stoppages and downtime.

- Eliminates expense, down time and safety concerns fo installing/maintaining electric submersible.

Dolphin Strainer

- Available from 1.5″ — 6″

- Always Floats Upright

- Tough, Shock-Proof

- Corrosion Proof

Oil Recovery Units

Recovery Unit Includes:

- Portable Pump Units (2 – 60 gpm)

- 1-1/2″ or 2″ Alpha Skimmmer

- Electric or Gasoline Drive

- 10 feet of non-floating hose and 30 feet of floating Hose with 3 sets of quick connect fittings

Alpha Skimmer

- Skims Oil and Other Effluents

- Adjustable Intake Weir (for thin or thick layers)

- Stainless Steel Construction

- Optional Screen Kits

- Optional Folding Design For Manways

Options

- Oil Water Separator

- Air, Diesel or Hydraulic Drive

- 2″, 3″ or 4″ Alpha Skimmer

- Stationary Pump Units (up to 265 gpm)

Mining Pumps Resources

Positive Displacement Pump Selection

Pump Sets Suitable for Clean Liquids

| Pump | Maximum Capacity | Maximum Total Head | Motor Rating | Max. Total Suction Lift | Pump rev/min | ||||||||

| m3/hr | US gpm | m H2O |

bar | ft H2O |

lb/in2 | up to 75 cSt |

1000 cSt |

Water and to 75 cSt |

1000 cSt | ||||

| hp | hp | m H2O |

ft H2O |

m H2O |

ft H2O |

||||||||

| L75 | 1.5 | 6.6 | 30 | 3 | 100 | 45 | 0.75 | 1 | 7 | 23 | 6.1 | 20 | 1760 |

| L100 | 3 | 13.2 | 30 | 3 | 100 | 45 | 1.5 | 2 | 7 | 23 | 6.1 | 20 | 1760 |

| L125 | 5 | 21.6 | 30 | 3 | 100 | 45 | 1.5 | 3 | 7 | 23 | 6.1 | 20 | 1440 |

| L150 | 10 | 43.2 | 30 | 3 | 100 | 45 | 3 | 5.5 | 6.7 | 22 | 6.1 | 20 | 1370 |

| L200 | 15 | 66 | 30 | 3 | 100 | 45 | 5.5 | 7.5 | 6.7 | 22 | 5.4 | 18 | 1250 |

| L300 | 30 | 132 | 30 | 3 | 100 | 45 | 10 | 15 | 6 | 20 | 5.4 | 18 | 850 |

| L400 | 60 | 264 | 30 | 3 | 100 | 45 | 15 | 30 | 6 | 20 | 5.4 | 18 | 850 |

| H75 | 1.5 | 6.6 | 45 | 4.5 | 150 | 65 | 0.75 | 1.5 | 7 | 23 | 6.1 | 20 | 1550 |

| 75 | 7.5 | 250 | 110 | 1 | |||||||||

| H100 | 3 | 13.2 | 53 | 5.3 | 175 | 75 | 1.5 | 3 | 7 | 23 | 6.1 | 20 | 1500 |

| 75 | 7.5 | 250 | 110 | 2 | |||||||||

| H125 | 5 | 21.6 | 45 | 4.5 | 150 | 65 | 2 | 5.5 | 7 | 23 | 6.1 | 20 | 1350 |

| 75 | 7.5 | 250 | 110 | 3 | |||||||||

| H150 | 10 | 43.2 | 60 | 6 | 200 | 87 | 5.5 | 7.5 | 7 | 23 | 6.1 | 20 | 1250 |

| 75 | 7.5 | 250 | 110 | 7.5 | |||||||||

| H200 | 15 | 66 | 45 | 4.5 | 150 | 65 | 5.5 | 10 | 6.7 | 22 | 6.1 | 20 | 1030 |

| 75 | 7.5 | 250 | 110 | 7.5 | |||||||||

| H300 | 22.5 | 100 | 53 | 5.3 | 175 | 75 | 10 | 20 | 6 | 20 | 6 | 20 | 960 |

| 75 | 7.5 | 250 | 110 | 15 | |||||||||

| H400 | 45 | 200 | 53 | 5.3 | 175 | 75 | 15 | 40 | 6 | 20 | 6 | 20 | 960 |

| 75 | 7.5 | 250 | 110 | 20 | |||||||||

Pump Sets Suitable for Dirty Liquids

| Pump | Capacity | Maximum Total Head | Motor Rating | Max. Total Suction Lift | Pump rev/min | ||||||||

| m3/hr | US gpm | m H2O | bar | ft H2O | lb/in2 | up to 75 cSt | 2500 cSt | Water and to 75 cSt | 2500 cSt | ||||

| hp | hp | m H2O | ft H2O | m H2O | ft H2O | ||||||||

| L100 | 2 | 9 | 30 | 3 | 100 | 45 | 1 | 2 | 8.2 | 27 | 5.2 | 17 | 1200 |

| L125 | 3 | 13.2 | 30 | 3 | 100 | 45 | 1.5 | 3 | 8.2 | 27 | 5.2 | 17 | 900 |

| L150 | 6 | 26.4 | 30 | 3 | 100 | 45 | 2 | 5.5 | 8.2 | 27 | 5.2 | 17 | 850 |

| L200 | 10 | 44.4 | 30 | 3 | 100 | 45 | 4 | 7.5 | 7.5 | 25 | 5.2 | 17 | 850 |

| L300 | 20 | 90 | 30 | 3 | 100 | 45 | 7.5 | 7.5 | 7.5 | 25 | 4.5 | 15 | 570 |

| L400 | 40 | 180 | 30 | 3 | 100 | 45 | 10 | 30 | 7.5 | 25 | 4.5 | 15 | 570 |

| H100 | 2 | 9 | 53 | 5.3 | 175 | 75 | 1 | 3 | 8.2 | 27 | 5.2 | 17 | 1000 |

| 75 | 7.5 | 250 | 110 | 1.5 | |||||||||

| H125 | 3 | 13.2 | 45 | 4.5 | 150 | 65 | 1.5 | 5.5 | 8.2 | 27 | 5.2 | 17 | 850 |

| 75 | 7.5 | 250 | 110 | 2 | |||||||||

| H150 | 6 | 26.4 | 55 | 5.5 | 180 | 78 | 3 | 7.5 | 8.2 | 27 | 5.2 | 17 | 800 |

| 75 | 7.5 | 250 | 110 | 4 | |||||||||

| H200 | 10 | 44.4 | 55 | 5.5 | 180 | 78 | 4 | 10 | 7.5 | 25 | 5.2 | 17 | 720 |

| 75 | 7.5 | 250 | 110 | 5.5 | |||||||||

| H300 | 15 | 55 | 60 | 6 | 200 | 87 | 7.5 | 20 | 7.5 | 25 | 5.2 | 17 | 650 |

| 75 | 7.5 | 250 | 110 | 7.5 | |||||||||

| H400 | 30 | 132 | 60 | 6 | 200 | 87 | 15 | 40 | 7.5 | 25 | 5.2 | 17 | 650 |

| 75 | 7.5 | 250 | 110 | 15 | |||||||||

The capacity of each Megator positive displacement pump is directly proportional to the pump speed. Therefore any capacity can be interpolated from the tables above. The pump curve is therefore a straight line.

Example

Application = clean water

Total head = 22 metres

Capacity required = 8m3/hr

- From the clean liquids table select a pump with a maximum total head equal to or greater than total head required

- Select a pump with a capacity equal to or greater than the capacity required

- Divide the listed pump speed by the listed capacity

- Multiply answer by the required capacity

L150 = 10m3/hr @ 1370 rpm

1370 ÷ 10 = 137

8m3/hr x 137 = 1096 rpm

Pump required = L150 @ 1096 rpm

Giving 8m3/hr at a maximum head of 30 metres

The Megator sliding shoe pump delivers its rated capacity at any head and at any suction lift within its range. The head developed is the head imposed by the system at the rated flow. A head capacity curve on the conventional basis would be a vertical straight line.

Intermediate Capacities

For intermediate capacities, the pumps can be run at speeds lower than those listed in the tables. The head is independent of the speed. The capacity, and the horsepower at a given head, are approximately proportional to the speed.

Motor Ratings

The standard motors listed provide for the maximum heads and, in the case of type H pumps, for an intermediate head. Where the heads are substantially below those listed , smaller motors can frequently be used.

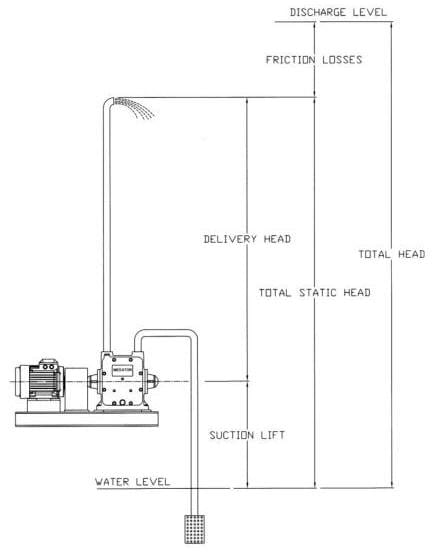

Suction Lift

The suction lifts listed assume normal temperature and sea level elevation. Installations combining suction lift with temperatures above normal and elevations above sea level should be referred to Megator.

Temperature

The ratings listed in the tables are valid for temperatures up to 38ƒC (100°F), subject to the above note on suction lift. Where higher temperatures are involved, it is advisable to consider them in conjunction with the other working conditions and such cases should be referred to Megator.

Dirty Liquids

Reduced pump speeds give a markedly increased resistance to wear, and the high suction ratings are recommended for dirty liquids. Under severe conditions still lower speeds may provide the most economical installation.

Pump Selection Resources

Useful Pumping Data

Piping

The size of pipe should not be smaller than the pump ports and, for long pipe runs or when handling viscous liquids should generally be larger. For other than very simple pipe runs, the actual pipe losses should be calculated using loss-of-head curves, as they may be a major part of the total head on the pump. Easy bends should be used and sharp elbows and tees avoided, to avoid loss of capacity or difficulty in priming due to air leaks.

Net Positive Suction Head (NPSH)

NPSH available is the absolute pressure of the liquid at the pump entry less its vapour pressure at the pumping temperature. It is an expression of the service conditions and is the maximum absolute pressure available at the pump entry to overcome the suction losses of the pump itself.

NPSH required is the minimum absolute pressure necessary at the pump entry to maintain the required flow without cavitation. The NPSH required for any pump is the standard absolute atmospheric pressure (10.4 m or 34 ft of water) less the listed suction lift of the pump at normal temperature and pressure.

Specific Gravity

The specific gravity of a liquid is the ratio of the weight of unit volume of the liquid to that of distilled water at 4°C. For normal pumping calculations, the specific gravity of clean fresh water can be taken as 1, and that of sea water 1.03.

Viscosity

In the SI system of units, dynamic viscosity is expressed as the Newton second per square meter (N*s/m2. In the CGS system of units, dynamic viscosity is expressed as dyne second per square centimetre (dyne*s/cm2) which is called a Poise.

The centipoise (cP), is a hundredth of a Poise and is the most common unit for dynamic viscosity. The dynamic viscosity for water at 20°C (68°F) is approximately 1 cP.

Kinematic viscosity is defined as the ratio of dynamic viscosity to density. The most common unit for kinematic viscosity is the centistoke (cSt), which is a hundredth of a Stoke. A Stoke is defined as 1 cm2/s and is taken from :

kinematic viscosity = dynamic viscosity ÷ density = Poise ÷ g/cm3

| Quantity | |||

|---|---|---|---|

| Imp gpm | U.S. gpm | m3/hr | lt/min |

| 1 | 1.2 | 0.273 | 4.546 |

| 0.833 | 1 | 0.227 | 3.785 |

| 3.667 | 4.4 | 1 | 16.67 |

| 0.22 | 0.264 | 0.06 | 1 |

| Volume | ||||

|---|---|---|---|---|

| Imp gal | U.S. gal | litres | m3 | ft3 |

| 1 | 1.2 | 4.546 | 0.00455 | 0.161 |

| 0.833 | 1 | 3.785 | 0.00379 | 0.134 |

| 0.22 | 0.264 | 1 | 0.001 | 0.0353 |

| 220 | 264.2 | 1000 | 1 | 35.32 |

| 6.229 | 7.475 | 28.32 | 0.028 | 1 |

| Pressure or Head | |||||

|---|---|---|---|---|---|

| ft H2O | lb/in2 | m H2O | kg/cm2 | in Hg | mm Hg |

| 1 | 0.434 | 0.305 | 0.031 | 0.881 | 22.42 |

| 2.307 | 1 | 0.703 | 0.07 | 2.036 | 51.71 |

| 3.281 | 1.422 | 1 | 0.1 | 2.896 | 73.55 |

| 32.81 | 14.22 | 10 | 1 | 28.96 | 735.5 |

| 1.133 | 0.491 | 0.345 | 0.035 | 1 | 25.4 |

| 0.045 | 0.019 | 0.014 | 0.001 | 0.039 | 1 |

Frequently Asked Questions

Does the sliding shoe pump require an additional priming device?

No, self-priming of the sliding shoe pump is spontaneous, without the use of an additional priming device. The only requirement is that the pump is filled with liquid before first start, or after a long shutdown.

Will the sliding shoe pump be damaged if left running on a dry suction?

No, the sliding shoe pump remains full of liquid even when it has a completely dry suction. It can run for long periods without damage.

Does the suction pipe require a foot-valve when using the sliding shoe pump?

No, the sliding shoe pump will displace any amount of air from the suction pipe.

Can an isolating valve be installed to the discharge pipework?

Yes, but any positive displacement pump will develop a dangerously high pressure, if run with the discharge throttled or shut off. If an isolating valve is fitted to the suction pipework (or if it is possible for an excessive head to be imposed on the pump by any other cause), then the pump must be installed with a pressure relief valve, which is available as an option on all sliding shoe pumps.

Can a star-delta starter be used on electric driven sliding shoe pumps?

No, when changing from star to delta, there is – for a fraction of a second – a stage where the pump will stop and would effectively be starting the pump in delta. We would recommend using direct-on-line starters or ‘soft start’ starters.

What type of suction strainer should be used with the sliding shoe pump?

The suction pipe must be fitted with a strainer of adequate size. The total area of the holes should be approximately three to four times the cross sectional area of the pipe. The Megator Dolphin Strainer is ideally suited to this application.

Can Megator pumps run in parallel?

All Megator pumps will operate in parallel with one another, or with other pumps, but certain points should be observed with regards to the piping. A common suction pipe to two or more pumps may cause one pump to interfere with the effective priming of another. each pump should preferably have an individual suction line. If this is not possible, each pump should be fitted with a non return valve.